Introduction

Iron is extracted in a large container called a blast furnace from its ore, hematite

Modern blast furnaces produce approximately 10,000 tonnes of iron per day

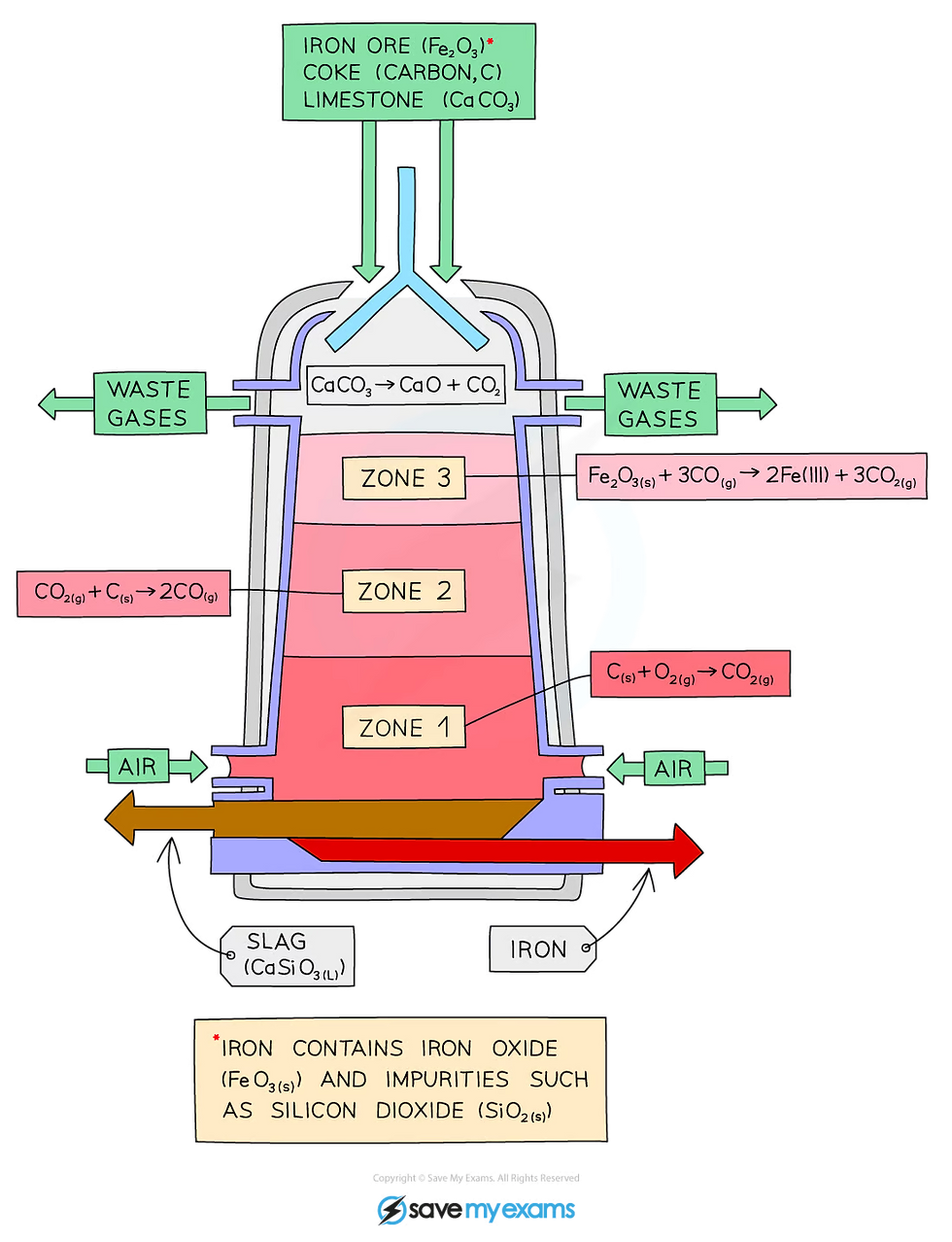

The blast furnace

The raw materials: iron ore (hematite), coke (an impure form of carbon), and limestone are added into the top of the blast furnace

Hot air is blown into the bottom

Zone 1

Coke burns in the hot air forming carbon dioxide

The reaction is exothermic so it gives off heat, heating the furnace

carbon + oxygen → carbon dioxide

Zone 2

At the high temperatures in the furnace, more coke reacts with carbon dioxide forming carbon monoxide

Carbon dioxide has been reduced to carbon monoxide

carbon + carbon dioxide → carbon monoxide

Zone 3

Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron

This will melt and collect at the bottom of the furnace, where it is tapped off

iron(III) oxide + carbon monoxide → iron + carbon dioxide

Limestone (calcium carbonate) is added to the furnace to remove impurities in the ore

The calcium carbonate in the limestone thermally decomposes to form calcium oxide

calcium carbonate → calcium oxide + carbon dioxide

The calcium oxide formed reacts with the silicon dioxide, which is an impurity in the iron ore, to form calcium silicate

This melts and collects as a molten slag floating on top of the molten iron, which is tapped off separately

calcium oxide + silicon dioxide → calcium silicate

Zone 1

The burning of carbon (coke) to provide heat and produce carbon dioxide:

C (s) + O2 (g) → CO2 (g)

Zone 2

The reduction of carbon dioxide to carbon monoxide:

CO2 (g) + C (s) → 2CO (g)

Zone 3

The reduction of iron(III) oxide by carbon monoxide:

Fe2O3 (s) + 3CO (g) → 2Fe (I) + 3CO2 (g)

The thermal decomposition of calcium carbonate (limestone) to produce calcium oxide:

CaCO3 (s) → CaO (s) + CO2 (g)

The formation of slag:

CaO (s) + SiO2 (s) → CaSiO3 (l)

What are the main products and by-products of the blast furnace process?

How is the iron extracted from the blast furnace further processed to make steel?

What environmental impacts are associated with the extraction of iron?

How does the reactivity series influence the method used to extract iron?

What are some modern advancements in the extraction of iron that aim to reduce environmental impact?